Securing Graphite Supply Chain for EV Batteries

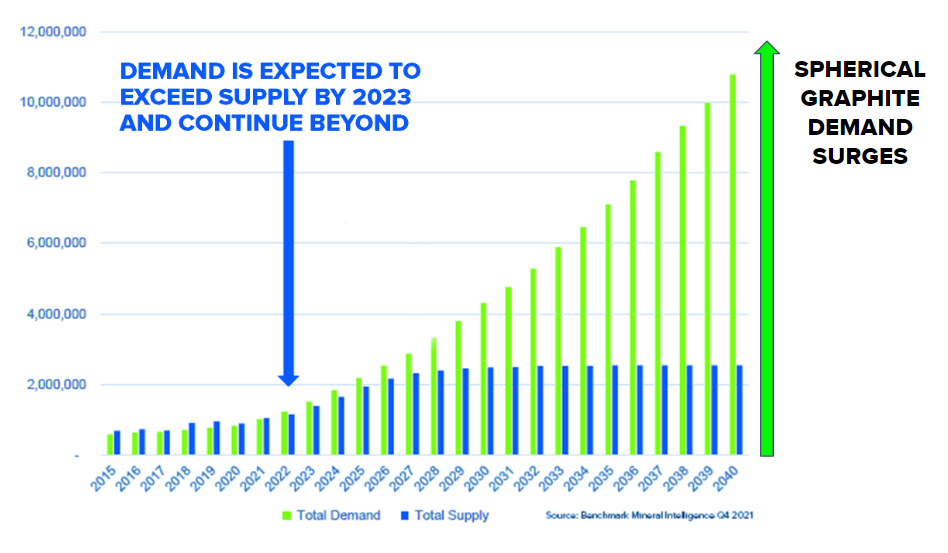

Global Graphite Demand Has Exceeded Supply!

Have you Secured your Supply Chain with the Critical Mineral, Graphite?

Get ahead of the Graphite shortage with NanoTerraTech’s innovative solution – BIO-Graphite.

Our Drop-In Solution, is Scalable and Sustainable.

The Role of Graphite in the EV Battery Market:

How the Shortage is Affecting Supply Chains

As the demand for electric vehicles (EVs) grows, the graphite market is experiencing an unprecedented shortage. Graphite is a critical component of EV batteries, and with limited supply, the entire EV industry is facing significant challenges. In this article, I will explore the role of graphite in the EV battery market, the current shortage, and how it is affecting supply chains. Additionally, I will discuss the sustainability concerns associated with graphite mining and the potential for creating graphite from forestry waste.

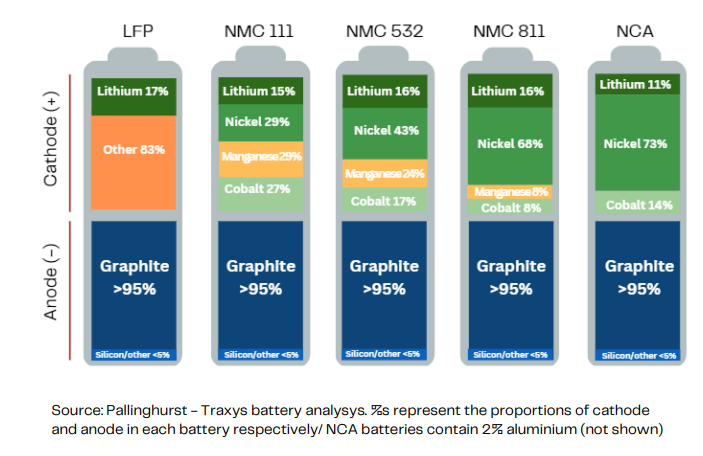

The Importance of Graphite in EV Battery Production

Graphite is a critical component of lithium-ion batteries, which are the primary source of energy for electric vehicles. The anode of a lithium-ion battery is made up of graphite, which provides a stable and reliable source of energy. It allows the battery to discharge and recharge efficiently and can withstand the high temperatures generated during charging and discharging.

Graphite is also essential to the overall performance of the battery. The quality and purity of the graphite can impact the battery’s energy density, charge rate, and cycle life. Therefore, it is crucial to use high-quality graphite in EV battery production to ensure optimal performance and longevity.

.

The Current Graphite Shortage and Its Impact on Supply Chains

The graphite market is experiencing a severe shortage due to a combination of factors. The primary cause is the rapid growth of the EV market, which has led to an increase in demand for graphite. At the same time, there has been a lack of investment in graphite mining, which has limited the supply of natural graphite.

Additionally, the production of fossil fuel-derived synthetic graphite is very energy-intensive and not sustainable. This has led to a shift towards natural graphite, which is more environmentally friendly but also more difficult to mine.

The shortage of graphite has had a significant impact on the EV supply chain. Manufacturers are struggling to secure a reliable source of high-quality graphite, which has led to delays in production and increased costs. The shortage has also led to concerns about the security of supply chains, as many of the world’s graphite mines are concentrated in a few countries.

Sustainability Concerns with Graphite Mining

The production of graphite is not without its sustainability concerns. Traditional graphite mining methods are energy-intensive and can have a significant impact on the environment. The mining process involves the use of heavy machinery and chemicals, which can lead to deforestation, soil erosion, and water pollution.

To address these concerns, we are creating BIO-Graphite from forestry waste. Our approach involves our proprietary platform technology that uses renewable energy and has massively lower environmental impact than traditional graphite mining or synthetic graphite production. There is hope for a more sustainable future through innovative approaches, as the demand for EVs continues to grow. It is essential to find sustainable solutions to ensure a secure supply of high-quality graphite for battery production.

Call to Action

If you are interested in learning more about the impact of Graphite on the EV industry and what you can do to support sustainable solutions while securing Graphite in your supply chain, please join our Waitlist to be the first to know as product becomes available. Together, we can work towards a more sustainable future for the EV industry.